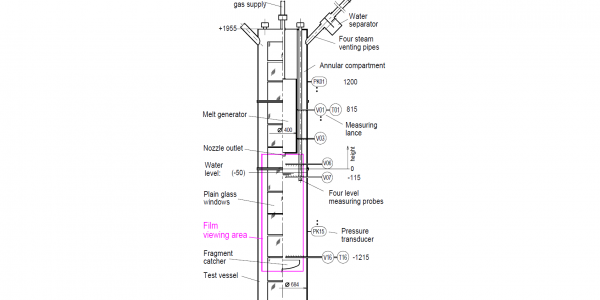

PREMIX

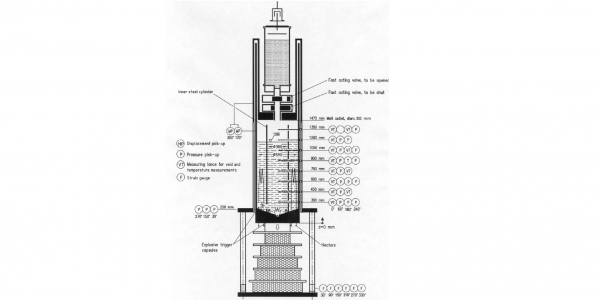

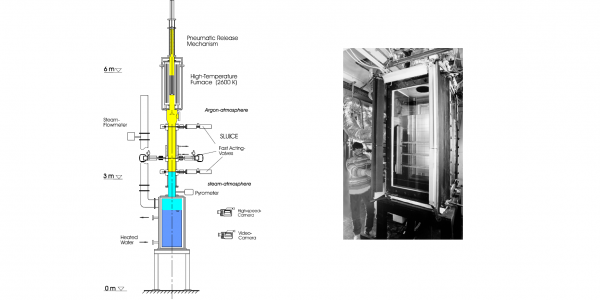

The PREMIX experiments have been performed to study the premixing of sizable amounts of very hot oxidic melts with water when being released as a jet in a reasonably characterized way and with full optical access. Alumina at 2600 K from a thermite reaction was used to simulate the corium melt. A technique has been developed to retain the molten iron in the source so that the contribution of iron to the melt is well below 10 %. PREMIX involves the full physics of the mixing process including jet break-up and melt drop fragmentation. But, of course, on the other hand, the initial and boundary conditions are more difficult to control and to vary compared to experiments with solid spheres such as QUEOS.