SIMECO program at KTH was performed to investigate the heat transfer of natural convection in an internal heated liquid pool, simulating a molten corium pool which may be formed in the reactor lower plenum during a severe accident.

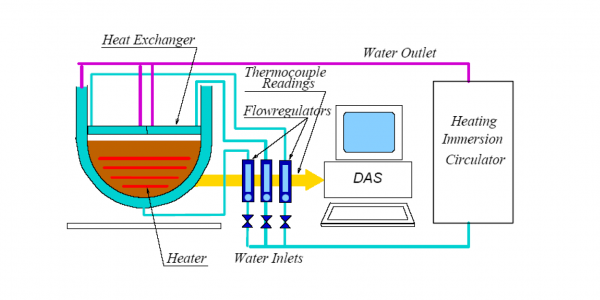

The SIMECO (SImulation of MElt COolability) test facility consists of a slice type vessel, which includes a semi-circular section and a vertical section, representing the lower head of the reactor vessel. The size of the facility is scaled to be 1/8 of prototypic PWR type reactors. Fig.1 shows a schematic of the facility and Fig.2 shows the main dimensions of the vessel test section. The diameter and height of the test section are 620 mm and 530 mm, respectively. The width of the test section is 90 mm. The front and back faces of the facility are insulated in order to decrease heat losses. The vessel’s wall, represented by a 23-mm thick brass plate, is cooled by a regulated water loop. On the top of the vessel a heat exchanger with regulated water loops is employed to measure the upward heat transfer. The sideways and downward heat fluxes are measured by employing array of thermocouples at several different angular positions. Practically isothermal boundary conditions are provided at pool boundaries. A cable-type heater 3 mm in diameter and 4 m in length is submerged in the pool and provides internal heating. A heat exchanger mounted on the exit of cooling water, is employed to maintain the cooling capacity of the water. The isothermal bath is designed to provide constant temperature. A circulation pump was mounted in order to establish necessary flow rate. One digital and one analog flowmeter were mounted to measure water flow through the wall of the slice, while one analog flowmeter is used to measure the flow in the upper heat exchanger.

Facility is in operation.